Loading... Please wait...

Loading... Please wait...Currency Displayed in

- Home

- Pressure Regulators & Accessories

- Stainless Steel Corrosive Gas 1-Stage PM Regs

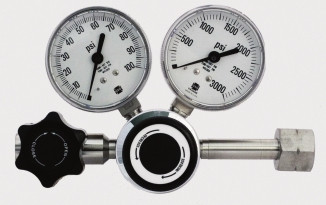

- Economical Corrosive Gas Stainless Steel High Purity B8 Single Stage Pressure Regulator Model 3452PM Del Press. 5-50 psig, Inlet Press. 990 psig Max PANEL MOUNT

Categories

- Expedite shipping charge

- Medical Products

- PVC Products

- Tubing Copper

- LifeGuard Safety Hoses Pigtails Brass

- LifeGuard Safety Hoses Pigtails Stainless Steel

- Cryogenic Equipment

- Tubing Stainless Steel Seamless Instrument Grade

- Lecture Bottle Equipment

- Indoor Gas Cylinder Safety Storage Cabinets

- Outdoor Gas Cylinder Safety Storage Cabinets

- Gas Cylinder Warming, Heating Blankets/Jackets

- Gas Cylinder Heating & Warming Products

- Gas Cylinder Safety Storage Equipment

- Cylinder Bench Mounting Brackets

- Cylinder Double Sided Floor Stands

- Cylinder Double Sided Process Racks

- Cylinder Safety Cap Lockable (Snap Cap)

- Cylinder Single Sided Process Racks

- Cylinder Single Sided Wall/Floor Stands

- Cylinder Stands

- Cylinder Stands for Lecture Bottles

- Cylinder Storage Process Racks

- Cylinder Storage Racks

- Cylinder Wall Mounting Brackets

- Fire Resistant Wall Barrier Panels

- Mobile Cylinder Carts

- Gas Cylinder Safety Storage Equip Stainless Steel

- Cylinder Hand Trucks & Firewall Cyl Hand Trucks

- Pressure Regulators & Accessories

- Adjustable Fixed Flow Corrosive Regulators

- Adjustable Fixed Flow Non-Corrosive Regulators

- Brackets For Mounting Pressure Regulators

- Brass General Purpose Non-Corrosive 1-Stage Regs

- Brass General Purpose Non-Corrosive 2-Stage Regs

- Brass High Flow - Piston-Sensed Regulator

- Brass High Flow High Purity Line Regulators

- Brass High Flow High Purity Regulators

- Brass High Pressure Regulators

- Brass High Pressure Regulators Very High

- Brass High Purity High Flow Single Stage Regs

- Brass High Purity Line Pressure Regulators

- Brass High Purity Single Stage Panel Mount Regs

- Brass High Purity Single Stage Pressure Regulators

- Brass High Purity Two Stage Pressure Regulators

- Corrosive Gas Single Stage Regulators

- Demand Flow Aluminum Regulators (Buna-N)

- Demand Flow Aluminum Regulators (Viton®)

- Disposable Cyl Nickel Plated Brass Non-Corrosive

- Disposable Cylinder Aluminum Non-Corrosive Regs

- Disposable Cylinder Stainless Steel Corrosive Regs

- Laser Cutting Brass Pressure Regulators

- Lecture Bottle Aluminum Regulators

- Lecture Bottle Chrome Plated Brass Regulators

- Lecture Bottle Stainless Steel Regulators

- Low Pressure High Purity Non-Corrosive Line Regs

- Low Pressure Non-Corrosive Zinc Line Regs

- Stainless Steel Corrosive Gas 1-Stage Line Regs

- Stainless Steel Corrosive Gas 1-Stage PM Regs

- Stainless Steel Corrosive Gas 1-Stage Regulators

- Stainless Steel Corrosive Gas 2-Stage Regs

- Stainless Steel Critical Purity 2-Stage Regs

- Stainless Steel High Flow - Piston-Sensed Regs

- Stainless Steel High Flow High Purity Line Regs

- Stainless Steel High Flow High Purity Regulators

- Stainless Steel High Pressure Regulators

- Stainless Steel High Purity 1-Stage Panel Mt Regs

- Stainless Steel High Purity 2-Stage Pressure Regs

- Stainless Steel High Purity High Flow 1-Stage Regs

- Stainless Steel High Purity Line Pressure Regs

- Stainless Steel High Purity Single Stage Pressure

- Manifolds,Changeover, Header, Protocol

- Auto-Logic® II Fully Automatic Touch Screen

- Brass Double Row Header Manifolds

- Brass Left Bank Single Row Header Manifolds

- Brass Right Bank Single Row Header Manifolds

- Dual Station Brass Protocol Manifolds

- Dual Station Stainless Steel Protocol Manifolds

- Economical High Purity Semi-Auto Brass Changeover

- High Purity High Flow Semi-Auto Brass Changeover

- Economical High Purity Semi-Auto S.S. Changeover

- High Purity Semi-Auto Brass Changeover Manifolds

- High Purity Semi-Auto S.S. Changeover Manifolds

- NEMA4 Economical H/P Semi-Auto Brass Changeover

- NEMA4 Economical H/P Semi-Auto S.S. Changeover

- NEMA4X Enclosure H/P Semi-Auto Brass Changeover

- NEMA4X Enclosure H/P Semi-Auto S.S. Changeover

- S.S. Double Row Header Manifolds

- S.S. Left Bank Single Row Header Manifold

- S.S. Right Bank Single Row Header Manifold

- Single Station Brass Protocol Manifolds

- Single Station Stainless Steel Protocol Manifolds

- Ultra-Logic® Advanced Fully Auto Touch screen

- Manifold Alarms & Pressure Switches

- 912 HUB Connects Up To 3 Devices

- 912-AVA Single Point Audio/Visual Alarm Module

- 913 Alarm Module

- 914-AVA Changeover Audio/Visual Alarm Module

- 914/916/917 Brass Pressure Switch For Flammables

- 914/916/917 Brass Pressure Switches

- 914/916/917 Stainless Steel P/Switch Flammables

- 914/916/917 Stainless Steel Pressure Switch

- 914/918 HUB Connects Up To 3 Devices

- AVD-45 Auto-Dialer

- Brass Low Gas Pressure Alarms

- Stainless Steel Low Gas Pressure Alarms

- UPS Power Battery Backup - CS350

- Point Of Use Panels Multiple Source Panels

- 1 Regulator Brass POU Multiple Source Panels

- 1 Regulator S.S. POU Multiple Source Panels

- 2 Regulators Brass POU Multiple Source Panels

- 2 Regulators S.S. POU Multiple Source Panels

- 3 Regulators Brass POU Multiple Source Panels

- 3 Regulators S.S. POU Multiple Source Panels

- 4 Regulators Brass POU Multiple Source Panels

- 4 Regulators S.S. POU Multiple Source Panels

- Point Of Use Panels Single Source Panels

- Cylinder Scales & Ramps

- CGA Cylinder Connections And Gaskets

- Electronic Mass Flow Controllers & Flowmeters

- Fittings Instrument Grade Compression

- Brass Bulkhead Unions Compression X Compression

- Brass Female Connectors Compression X Female NPT

- Brass Female Elbows Compression X Female NPT

- Brass Male Connectors Compression X Male NPT

- Brass Male Elbows Compression X Male NPT

- Brass Reducing Unions Compression X Compression

- Brass Union Elbows Compression X Compression

- Brass Union Tees Compression All Ends

- Brass Unions Compression X Compression

- Stainless Steel Bulkhead Unions Compression X Comp

- Stainless Steel Female Connectors Comp X Female

- Stainless Steel Female Elbows Compression X Female

- Stainless Steel Male Connectors Compression X Male

- Stainless Steel Male Elbows Compression X Male NPT

- Stainless Steel Reducing Unions Compression X Comp

- Stainless Steel Union Elbows Comp X Comp

- Stainless Steel Union Tees Compression All Ends

- Stainless Steel Unions Compression X Compression

- Fittings Instrument Grade Pipe

- Brass Female Elbow NPT Female X NPT Female

- Brass Female Hex Coupling NPT Female X NPT Female

- Brass Female Tee NPT Female All Ends

- Brass Hollow Hex Pipe Plug NPT Male

- Brass Hose Barbs NPT Male x Barb

- Brass Male Branch Tees NPT Male x NPT Female x NPT

- Brass Male Elbow NPT Male X NPT Male

- Brass Male Hex Nipple Long NPT Male X NPT Male

- Brass Male Hex Nipple NPT Male X NPT Male

- Brass Male Tees NPT Male All Ends

- Brass Pipe Cross NPT Female All Ends

- Brass Reducing Adapter NPT Female X NPT Male

- Brass Reducing Bushing NPT Male X NPT Female

- Brass Street Elbow NPT Male X NPT Female

- Brass Street Tees NPT Male x NPT Female x NPTF

- Stainless Steel Female Elbow NPT Female X NPTF

- Stainless Steel Female Hex Coupling NPTF X NPTF

- Stainless Steel Female Tee NPT Female All Ends

- Stainless Steel Hollow Hex Pipe Plug NPT Male

- Stainless Steel Hose Barbs NPT Male x Barb

- Stainless Steel Male Branch Tees NPT Male x NPTF

- Stainless Steel Male Elbow NPT Male X NPT Male

- Stainless Steel Male Hex Nipple Long NPTM X NPTM

- Stainless Steel Male Hex Nipple NPTM X NPTM

- Stainless Steel Male Tees NPT Male All Ends

- Stainless Steel Pipe Cross NPT Female All Ends

- Stainless Steel Reducing Adapter NPTFemale X NPTM

- Stainless Steel Reducing Bushing NPT Male X NPTF

- Stainless Steel Street Elbow NPT Male X NPT Female

- Stainless Steel Street Tees NPT Male x NPT Female

- Flash Arrestors

- Flowmeters & Accessories

- Economic Machined Acrylic Flowmeters Series 7923

- Flowmeter Bench Stand Fits Series 7920 & 7965

- Flowmeter Replacement Tubes 7920,40,41 150mm

- Flowmeter Series 7920 150mm Brass Without Valve

- Flowmeter Series 7920 150mm Brass With Valve

- Flowmeter Series 7920 150mm Stainless No Valve

- Flowmeter Series 7920 150mm Stainless With Valve

- Flowmeter Series 7965 65mm sccm Brass

- Flowmeter Series 7965 65mm slpm Brass

- Flowmeter Series 7965 65mm SCFH Brass

- Flowmeter Series 7965 65mm sccm Stainless Steel

- Flowmeter Series 7965 65mm slpm Stainless Steel

- Flowmeter Series 7965 65mm SCFH Stainless Steel

- Four Tube Flowmeters Series 7940 150mm Aluminum

- Four Tube Flowmeters Series 7940 150mm S.S.

- Large Flow Acrylic Flowmeters Series 7974 1/4"NPTF

- Large Flow Acrylic Flowmeters Series 7975 1" NPTF

- Multi-Tube Flowmeters Mixers 150mm Tubes, Aluminum

- Multi-Tube Flowmeters Mixers 150mm Tubes,Stainless

- Two Tube Gas Proportion Flowmeters 150mm Aluminum

- Two Tube Gas Proportion Flowmeters 150mm S.S.

- Gas Cylinder Wrenches

- Gas Filters & Coalescing Filters

- Brass In-Line Filters With #1, 2, micron filter

- Brass In-Line Filters With #5, 10, micron filter

- Brass In-Line Filters With #50, 100, micron filter

- Depth Gas Filters Stainless Steel 0.01 Microns

- Stainless Steel High Efficiency Coalescing Filters

- Stainless Steel In-Line Filters #1,2 micron filter

- Stainless Steel In-Line Filters #5 micron filter

- Stainless Steel In-Line Filters #10 micron filter

- Stainless Steel In-Line Filters #50 micron filter

- Stainless Steel In-Line Filters #100 micron filter

- Gas Leak Detection Equipment & Systems

- Gas Purifiers & Traps

- CO2 Carbon Dioxide Traps

- Gas Purifiers & Molecular Sieves For High Capacity

- Gas Purifiers & Molecular Sieves For High Pressure

- Hydrocarbon Traps Brass & Stainless Steel Fittings

- Indicating Moisture Traps Brass

- Indicating Moisture Traps Stainless Steel

- Mounting Clips For Traps

- Oxygen Removing Purifier For Hydrogen

- Oxygen Traps Brass & Stainless Steel Fittings

- Flexible Metal Hoses, Pigtails

- Pressure Gauges

- Purge Valve Assemblies

- Valves, Relief, Check, Needle, Control, Diaphragm

- Brass Relief Valves NPT X NPT

- Stainless Steel Relief Valves NPT X NPT

- Check Valves Brass, Monel, Stainless Steel

- HP Diaphragm Packless Valve Brass, S.S. 90° lever

- HP Diaphragm Packless Valve Brass&S.S. Multi-turn

- Lecture Bottle Control Valves BrassStainless Steel

- Manual Control Valves Stainless Steel, Monel

- Needle Valves Brass, Monel, Stainless Steel

- Teflon Tape and Sealants

- Tubing Cutters, Benders and Deburring Tools

Economical Corrosive Gas Stainless Steel High Purity B8 Single Stage Pressure Regulator Model 3452PM Del Press. 5-50 psig, Inlet Press. 990 psig Max PANEL MOUNT

Product Description

Add the CGA connection of your choice to the Order Instructions/Comments Section Box at Check out time. CGA Connections will be installed on your equipment at NO CHARGE FOR PARTS OR LABOR (EXCEPT FOR CGA'S 170, 180, 240, 296) CGA Connections are also sold separately and maybe Purchased by going under the CGA Connection Category. All outlet fittings and Connections are also sold separately and maybe purchased by going under our Compression or Pipe Fittings Categories.

PANEL MOUNT REGULATOR

| DESCRIPTION | ||||||||||||||||||

| The Series 3450 single stage regulators are specifically designed and constructed for use with difficult to handle gases, like chlorine and hydrogen chloride. The monel® diaphragm, inlet filter, poppet and nozzle assembly installed in a 316L stainless steel body create an economical high purity corrosive gas regulator for most applications. | ||||||||||||||||||

| FEATURES | ||||||||||||||||||

| • Hastelloy® internal parts for added corrosion resistance. • Encapsulated seat. • High purity diffusion resistant, metal diaphragm construction. • Diffusion resistant, diaphragm packless control valve installed on outlet as standard. • Designed to pass an inboard helium leak-rate test of 1x10 -9 cc per sec. • All parts ultrasonically cleaned prior to assembly. • Rear panel mounting holes. |

||||||||||||||||||

| APPLICATIONS | ||||||||||||||||||

| The 3450 Series regulators are ideal for use with many corrosive gases, such as chlorine, hydrogen chloride, boron trichloride, and boron triflouride. They are also useful for controlling the pressure of gas mixtures containing these corrosive gas components, particularly at higher concentration levels. | ||||||||||||||||||

| SPECIFICATIONS | ||||||||||||||||||

|

Max. Inlet Pressure: 990 psig

|

||||||||||||||||||